As anyone who’s worked in construction can tell you, nothing draws a crowd of “sidewalk superintendents” quite like the sight of someone else hard at work. Now, you can join the crowd without ever leaving your desk. Ferriot has installed a Go Pro camera on the ceiling in the production area, above the area where we’re assembling our new 2,250-ton Negri Bossi BI‑POWER injection molding press. Each week, Ferriot will update the photographs to allow checking in on the progress of the installation. In addition to using these photographs for sales and marketing purposes, the camera will let us document this milestone in our company history with a time-lapse video. To check on project status, visit our Negri Bossi Press Installation Progress page.

I’m happy to report the installation is proceeding on schedule (more or less), with the site preparation and floor reinforcement phases now complete. The concrete foundation we poured at the end of November has cured and the massive components of the press (one of which weighs 70 tons!) and its peripherals will be delivered on five semi-truck loads. Due to an unusually cold winter, the components must be inside our building for a few days and must reach room temperature before installation can begin. Installation should be completed by late February.

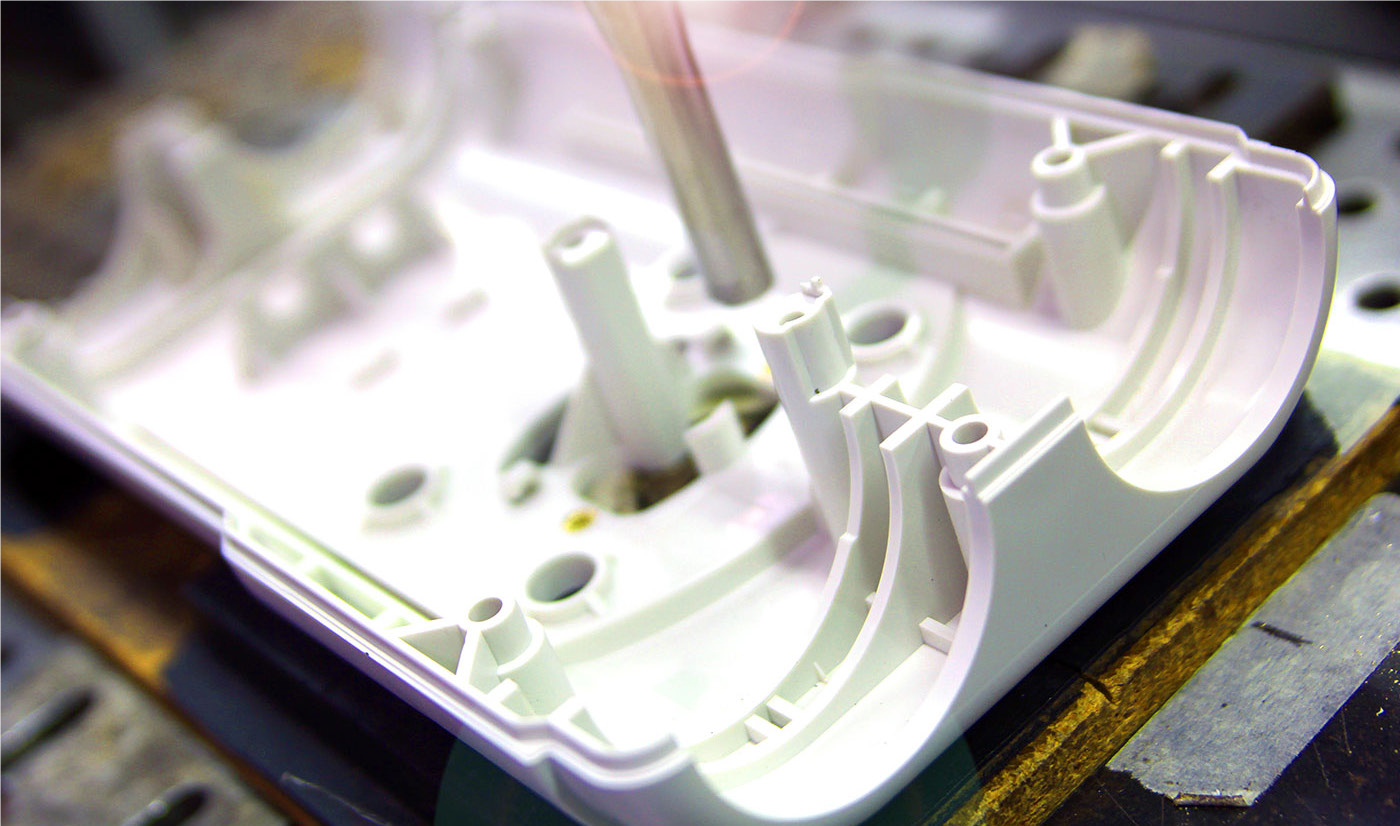

The press configuration we chose is designed to support producing the largest plastic parts we’ve ever handled. Once it’s installed, the press will allow us to boost production capacity, operate more efficiently, and reduce delivery times to our customers. The installation of the press is part of our long-term plant reconfiguration effort designed to use floor space more efficiently, boost labor productivity, simplify movement and the flow of work through the facility, and ease supervision.

The new press will have an integrated Columbia industrial PC and a variable delivery pump hydraulic system that allows for precise process control and high power efficiency. The support team at Negri Bossi will be able to monitor its operation remotely via the Internet at any time so they can perform diagnostics, troubleshooting, and intervention in real time.

We invite you to stop by the Negri Bossi press installation page to check out our progress. You can also follow us on LinkedIn, Facebook and Twitter.

If you want an overview of how a press of this type comes together, why not take a few minutes to watch a YouTube video that shows one of Negri Bossi’s larger Bi-Power presses being assembled? It’s available at https://youtu.be/bEmbwcb3oWs.

Interesting in hearing more or want notified when new blogs are released? Subscribe to our blog so you never miss an update.