If there’s one thing that every manufacturer knows, it’s the value of a good operator. Operators are champions of production, driving the performance, efficiency, and reliability of your plant processes.

Unfortunately, great operators are often wasted on repetitious manufacturing processes, where most of their time is spent on mundane tasks instead of work that requires more “brainpower” and finesse. On those monotonous tasks, if operators are being forced to act like a machine doing the same thing over and over again, why not get an actual machine to do it?

{% video_player “embed_player” overrideable=False, type=’scriptV4′, hide_playlist=True, viral_sharing=False, embed_button=False, autoplay=False, hidden_controls=False, loop=False, muted=False, full_width=False, width=’1920′, height=’1080′, player_id=’36066729675′, style=” %}

That’s the idea behind automation and using robots on the manufacturing floor. With the help of collaborative robots known as cobots, manufactures can achieve many benefits, including:

- Faster and more efficient processes

- Improved part performance and reliability

- Less downtime

- Labor reduction

What’s more, is that all these things can happen while also improving the jobs and lives of the operators. Contrary to popular belief, cobots weren’t made to replace operators but rather enhance the workflow and save them for more important tasks.

Here’s why Ferriot and other manufacturers are turning to the power of cobots to enhance plant productivity.

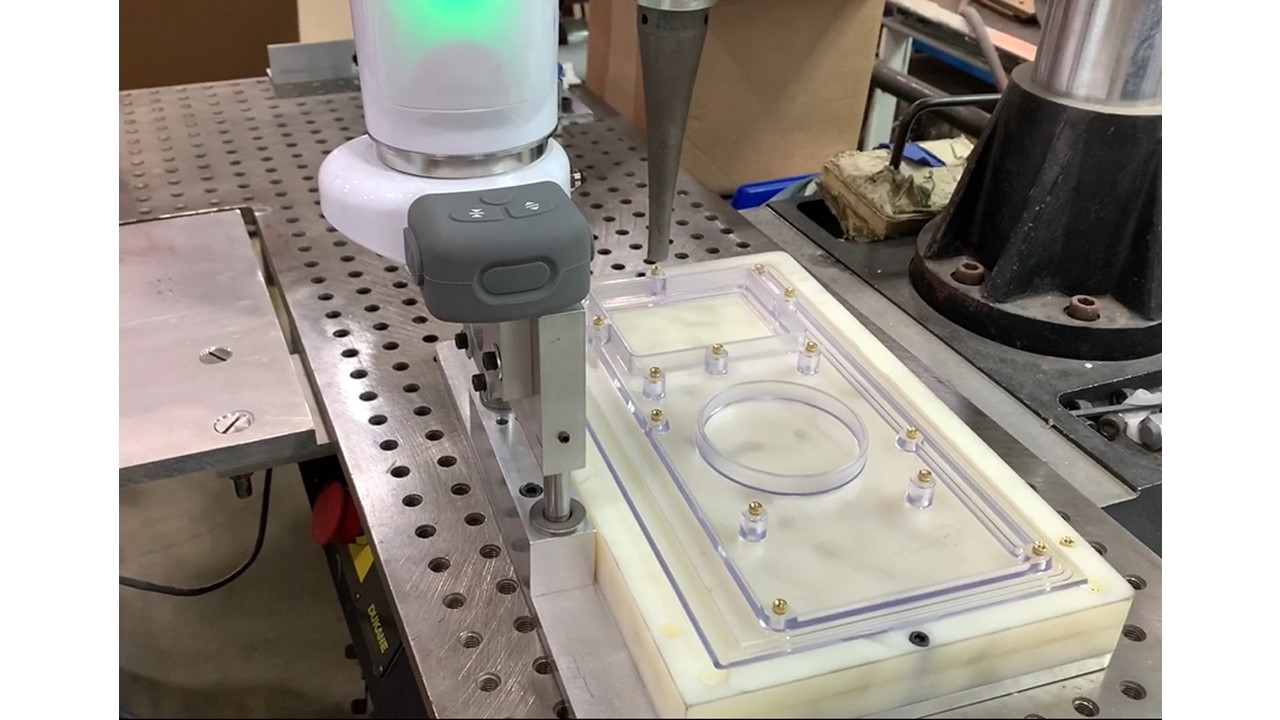

Cobot and Ultrasonic Welding Service

Cobot and Ultrasonic Welding Service

The High Cost of Manual Labor

A lot of manufacturing is doing the same thing over and over again. Unfortunately, humans weren’t made to do the same thing time after time with perfect reliability.

This lack of repeatability with human labor leads to significant inefficiencies over time, forcing manufacturers to accept a certain amount of lost time and bad products. It is human nature to find shortcuts, and people get bored doing the same thing over and over. There’s no value-added benefit of having people in control of these tasks. It leads to reduced quality and the need for more labor.

When an operator has to do every mundane task on the plant floor, it also forces unneeded wear and tear on their bodies. This leads to operator burnout, which is not only a hazard to their personal lives but can cause them to underperform at work.

Overworked operators also don’t have the time to critically analyze the parts they’re creating, which is bad for quality assurance. Operators are just moving parts and not really looking at them.

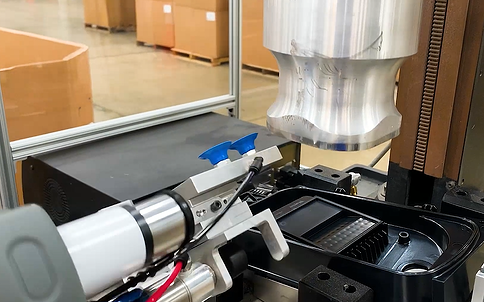

Cobot and Insert Welding Service

The Power of Cobots

With the power of today’s technology, manufacturers no longer have to rely on human operators to handle every production task. Cobots can now handle all the repetitive and tedious elements of manufacturing, leaving operators open for more complex tasks and part analysis.

Not only does this save time on assembly, but it also leads to higher quality and more consistent parts. Manufacturers looking to add cobots to their production lines can expect measurably better parts, sometimes in half the time.

None of this should be worrisome for the operator, as many often misconceive that a focus on manufacturing robots and automation will take away jobs from the people that previously did those tasks. Cobots are collaborative robots. They don’t take away jobs so much as they take away the bad parts of jobs, allowing operators to be happier, healthier, and more productive as they oversee the cobots and focus on more skilled work.

Ron Pack, Manufacturing Engineer at Ferriot, talked about the importance of cobots in a recent interview. “A person has to be involved somehow in almost everything with cobots, so you’re not taking away any jobs or disrupting operators,” said Ron. “But the more you can automate the mundane parts of manufacturing, the more your operators can look at the finished product and make sure it’s actually good. Operators are happier, and your parts are better. It’s a win-win.”

Better Manufacturing at Ferriot

Seeing the value that cobots offer to both manufacturers and operators, Ferriot has invested in new cobot technology to aid Ferriot’s team on the plant floor. Since the beginning of 2020, Ferriot has employed two cobots to assist our operators and improve our facility’s performance.

Currently, Ferriot’s cobots are working on six different parts, with plans to add four new parts to their workflows in the near future. “The increased efficiency and repeatability of the cobots has really been key,” said Ron. “In some of our more important areas, we’ve seen efficiency gains of 60 percent or more.”

Cobots have been a particular help in recent times due to the COVID-19 pandemic. They’ve allowed Ferriot to reposition its operators to better handle the changing environment in a time where recruiting new operators was difficult.

One thing is for certain – cobots will play an increasingly bigger role in the manufacturing plants of the future, creating better working environments for operators and manufacturers alike.

Is Your Culture a ‘Good Fit’ for New Technology? [Industry Week, Craig Ferriot interview]

Learn more: