When reviewing projects with your injection molder, remember to discuss what value–added or secondary services they provide beyond molding your parts. Consider selecting one company that can handle all of your custom injection molding, painting and decorating needs. Using an injection molder with comprehensive services that include painting and decoration capabilities saves time and lowers your cost.

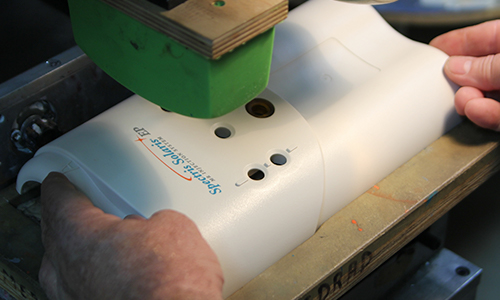

Two-color pad printing machine

When you work with an injection molding company that also does the painting and the decorating, your production lead time is minimized because no additional transit time is added to ship parts from the injection molder to the company providing the finishing services. This also means that there is no additional freight cost added to the final cost of the finished product.

Working with a company that does both processes in-house also means more time can be saved because full-service injection molders can optimize the production, painting, and decorating of your products efficiently and in a cost-effective manner. Manufacturing cells are flexible and customized for the products being made. A good example of this would be an enclosure with specific color requirements and a company logo. An injection molder with painting capability can look at the options of color matching the resin versus painting the parts once molded. This optimizes your products, and gives you options where cost, appearance and performance can be considered before making the final decision. Once you determine the process for achieving part color, the method to be used for application of the logo can be considered.

The most common choice for incorporating brand names, logos, instructions, and other markings on plastic products is pad printing. Many customers are drawn to pad printing because it provides the capability to place a 2D image onto a 3D surface. The process of pad printing utilizes a silicone pad, and its flexibility allows it to easily adapt to irregular surfaces that could have various textures or recessed areas.

In this example, pad printing is used for both two-color branding

and to provide warning instructions in black (top of part).

What are the advantages of pad printing?

When it comes to adding your brand or other information to your injection molded parts, pad printing offers some very valuable advantages:

- Adapts to irregular shapes and surfaces to print a clear, uniform image.

- Enables reasonably fast printing on complicated or challenging substrate materials.

- Ideal for transferring finely detailed images, such as instructional graphics and text.

- Generates repeatable and precise results, making it cost effective for high volume parts.

- Great where limited colors are required (up to four).

- Yields quality results even in small areas that require a lot of detail.

Pad printing is particularly useful when the surface on which the logo and product name is must appear on an irregular surface. In this case, the imprint area is curved rather than flat.

Pad printing is particularly useful when the surface on which the logo and product name is must appear on an irregular surface. In this case, the imprint area is curved rather than flat.

Is pad printing right for my product?

The pad printing process is commonly used on products in many industries and numerous applications including:

- Medical devices (syringes, surgical instruments, pumps and monitoring devices)

- Caps and closures (drink bottle caps, storage containers, etc.)

- Decorative designs/graphics appearing on consumer products (toy cars, balls, etc.)

- Automotive parts (turn signal indicators, control panels, etc.)

- TV and computer monitors

- Identification labels and serial numbers for many applications (electronic devices, industrial controls, etc.).

There are 2-color and 4-color options that provide durable results whether you’re printing company logos, product names, user instructions, and operational indicators.

What details are needed for your pad printing job?

To ensure the successful pad printing of your injection molded parts, you will need to provide specifications, graphics, and set up instructions. The list below is a great guide to help you prepare for your pad printing job:

- CAD, 2D drawing of part(s), noting graphic location(s).

- AI file noting size of all graphics.

- Estimated quantities per run or annual usage.

- Color specs (Pantone color numbers).

- Material of part (ABS, PC, etc.).

Visual instruction icons being pad printed

where controls will appear on the final product.

Are there additional pad printing costs?

Other than the ink needed, there are some one-time setup costs that could run between $1,000 and $1,500. Additional costs that you can expect when getting started with your pad printing project include:

| Holding Fixture to hold the part in place when printing | $550 |

| Artwork | $190 |

| Cliché image plate | $280 |

| Ink Color Match | $140 |

| Silicone Pad Print Pad | $75 |

One of the most common reasons our customers turn to pad printing is its cost-effectiveness. If you have high volume parts, need a limited number of colors and/or very small areas to print while maintaining high quality and tolerances, pad printing is a great choice.

Before any pad printing job, make sure that you review the project with your injection molder to discuss your unique requirements. They will know the questions to ask, and will understand how your application, shape, size, material and surface finish will impact your desired results allowing them to provide you with a quality product.

If you need further assistance, don’t hesitate to ask us your questions. We’re here to help!

Learn more:

- 3 Common Pad Printing Problems and How to Troubleshoot Them

- Don’t Make These Mistakes with Final Assembly Services

- 9 Reasons to Consider Painting Plastic Molded Parts

- What to Consider When Chrome Plating Plastics