Total Quality Management is critical to everything we do for our customers. At the end of the day, the goal is production readiness. Injection molded parts must be optimized for functionality, production consistency and ease of manufacturing. TQM includes everything from start to finish, from mold qualification to production quality.

However, for many of us at Ferriot, TQM is also our way of life. This is especially true for George Popov, the Quality Supervisor at Ferriot. George was able to take some time out of his busy schedule to discuss how Ferriot is dedicated to the process of continuous improvement when it comes to delivering quality to our customers.

Liz: How long have you been working in the quality field and with Ferriot as the quality supervisor?

George: I’ve been working over 10 years in quality. It’s getting close to three years with Ferriot, with about 10 months in a supervisory role.

Liz: What do you do at Ferriot as a quality supervisor?

George: I oversee the inspection team for both the molding and finishing departments. And I provide them with support on any issues they’re facing, direction on how to perform their responsibilities. Of course, there’s much more, but that’s basically what I do.

Liz: How large is your team?

George: It’s a four-person inspection team, with a backup inspector for each shift in the Molding department and two backup inspectors for the Finishing department. Having someone available during all hours of operation emphasizes how important delivering quality is for Ferriot.

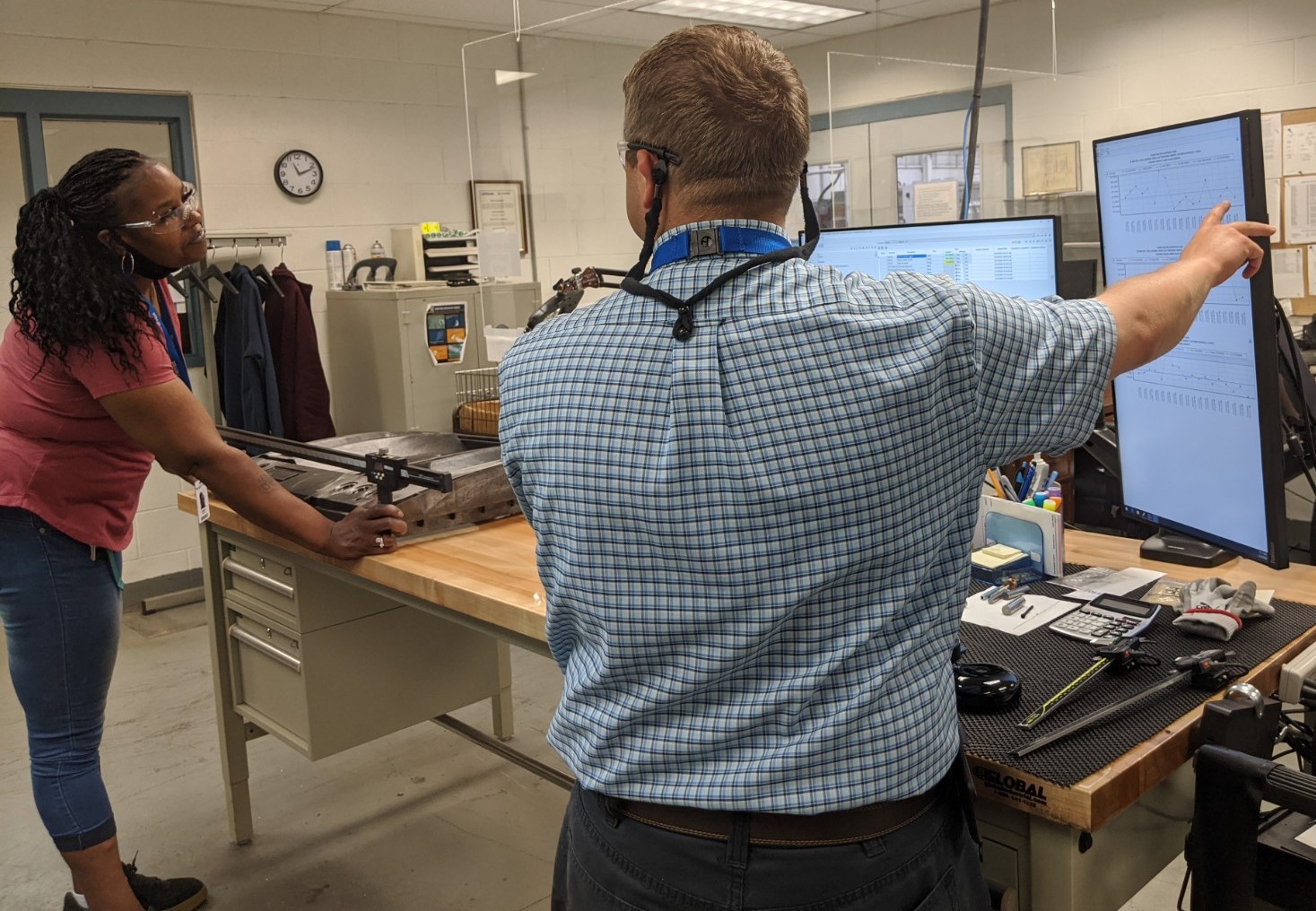

George Popov, Ferriot Quality Supervisor, reviewing in-process inspection dimensional trend charts with First Shift Inspector Markeet “Angel” Bradford.

Liz: What is involved with your position and responsibilities as the quality supervisor?

George: Of course, I’m making sure our inspectors are putting quality matters first and getting the right answers to anything that they might have questions about to assure we’re delivering the highest quality end products possible. However, it’s also about giving them guidance and direction on how to perform their responsibilities, and supporting them when they run into issues on the floor, or internally, and giving them the support that they need to make sure they feel comfortable doing their jobs.

Liz: How frequently do you interface with customers directly?

George: Whenever we have customer visits, typically that’s with our quality director and quality engineers. I make an effort to go out of my way to be sure I meet them, the customers, just so they know who I am, and in case they need to see me in the future. They need to know I’m accessible.

Liz: Describe what your work day is like at Ferriot as the quality supervisor.

George: My schedule is from seven to four, just so I can connect with the third shift inspector when I come in before she leaves. I’m here all day first shift, and then on second shift I also overlap with the second shift inspectors so that I can communicate with them in person, at least for part of their shift, to discuss any concerns and go over any pressing issues. I periodically check my emails to see if there’s anything that I need to address immediately, what I can put on the back burner for things that are not so pressing. I always make sure to get back to everybody as quickly as I can, but also as efficiently as I can.

I spend a lot of my time looking at inspection inputs, going over any issues with the inspectors, especially with my first shift team since I’m here most of the day.

I also make an inspection round on the floor and I’m increasing that as well, just so I’m aware of what’s happening out there in the molding department. I’m trying to be sure I have a feel for everything that goes on and where our quality team needs to place the most focus.

There’s also a lot of correspondence with cross functional teams, with the manufacturing department, the front office personnel, a lot of contact and correspondence with all the Ferriot engineers. I support them with issues that are occurring on the floor, helping them put out “fires” as they arise, helping them put together work instructions, quality alerts, and relaying critical information both internally and to customers. I’m the interface between the quality engineers and the inspectors. That makes up the bulk of my day.

Throughout the day, I’m also working on different quality department improvements. For example, we’ve moved away from an old paper system for inspection records to our online IQMS inspection. That’s been a challenge, but a good one. Transitions are always painful, but we know that they can be beautiful in the end.

Liz: It sounds like you have a number of hats to wear, and it’s an ongoing process of improvement, which is excellent to hear. Can you speak briefly about the advantages of that shift to IQMS you mentioned?

George: Absolutely. It’s just everything can be saved electronically now, so we have ease of access to all our inspection records. We also have SPC (statistical process control) available that we chart everything now so we can see trends. That helps us tremendously with process control on the manufacturing floor. When we see a process shift on our graphs, we can alert the manufacturing personnel so that they can make adjustments and take notes—something our old paperless system did not allow us to do.

With the old paper-based system, a lot of information was just put in storage. No one really saw what was happening unless a big issue would arise. And then it could really get ugly. We still have that paper system as a backup in case our system goes down, in case we lose power, or what have you. But it was just an archaic way to document our data and our customers were noticing that. It just wasn’t something that gave our customers confidence in us.

Now that we’ve gone electronic, it has caught our customer’s attention. They can see that, yes, we do care about quality, and we do care about the data we collect. It’s not just going to be put on paper and filed away. Everything’s documented, it’s very visible, easy to get to for review, and I think it’s just the right thing to do.

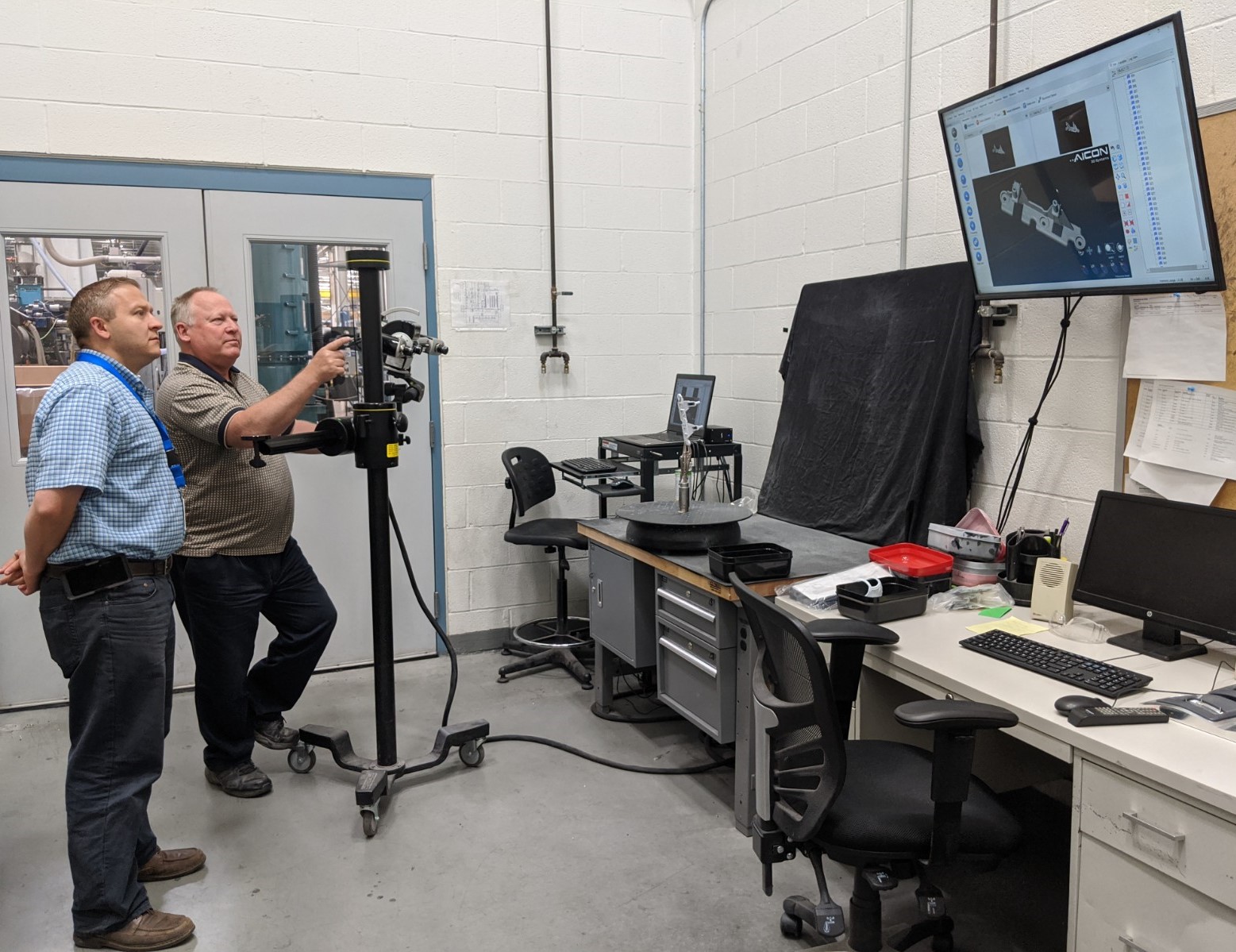

George and Quality Technician Walter Kravetz reviewing scanned model from the AICON smartScan Blue Light Scanner (by Hexagon Metrology) within Optocat software, before sending the file over for dimensional analysis in PolyWorks Inspector universal 3D dimensional analysis and quality control software.

Liz: What would you consider to be your biggest challenge on a day to day basis?

George: That would be making sure I have buy-in with our people. It is very important to get our inspectors on board with why we’re making changes. I know it’s been a challenge. They’ve been used to a paper system for many, many years. And now this change with new structure and evolving process improvements. Getting them through the transition period was a very difficult challenge. Some days are really good, and some days won’t be. But we continue to get through those challenging times. I also seek advice from other people, cross functional teams, and from my director. He’s been a good mentor for me.

It’s a valuable thing—learning how to deal with the challenge of transition and ongoing process improvements. If I can focus the inspectors on why we’re doing this so that they can see the vision as well, hopefully everyone appreciates the resulting benefits. Right now, it’s kind of hard, but we’re hitting several milestones. We’re understanding the system more and more each day. And I think that’s obviously making it easier for them to get on board. Sure, there’s still challenges. You’ll eventually run into something you haven’t run into before. We’d like to fix everything right now, or yesterday. But it just doesn’t happen that way. However, we’re chipping away at things each and every day and it shows in our ever-improving quality.

Liz: And I’m sure it’s going to provide great value to our customers in the long run.

In Part 2, we’ll discuss one of Ferriot’s new technology acquisitions, the AICON smartScan Structured Blue Light Scanner by Hexagon Metrology, and how it is helping the Ferriot Quality Team deliver quality like never before.

Learn more…

- Total Quality Management Services

- Does Your Manufacturer Have a Product Quality Audit in Place?

- Three Ways a Full-Service Contract Manufacturer Adds Value

- Request a Quality Audit