Team Ferriot recently enjoyed a visit from students at Akron’s NIHF STEM High School. The students toured our 200,000-square-foot office and manufacturing facilities to learn more about the latest manufacturing processes, technologies and varous injection molding career opportunities from engineering design to quality management. The following photo blog provides you with a glimpse at their tour.

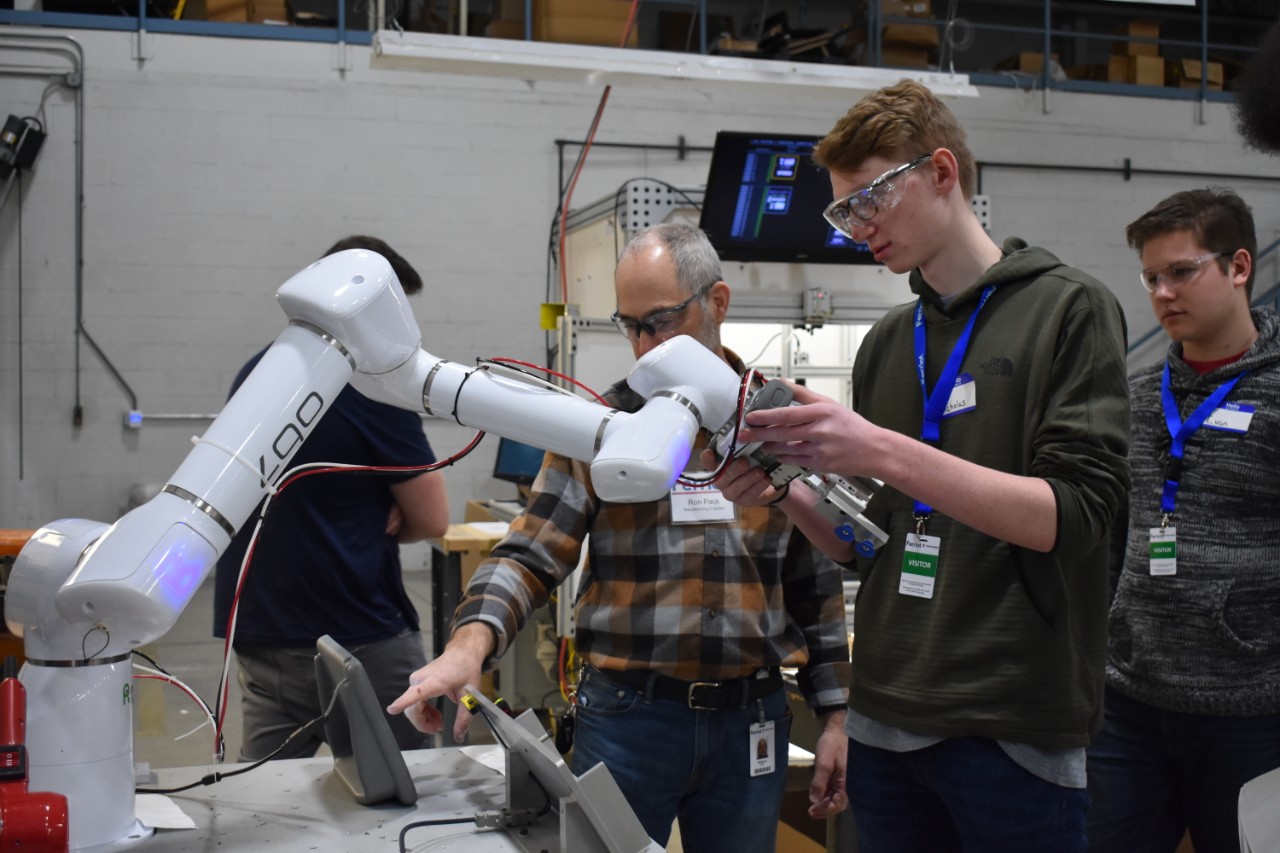

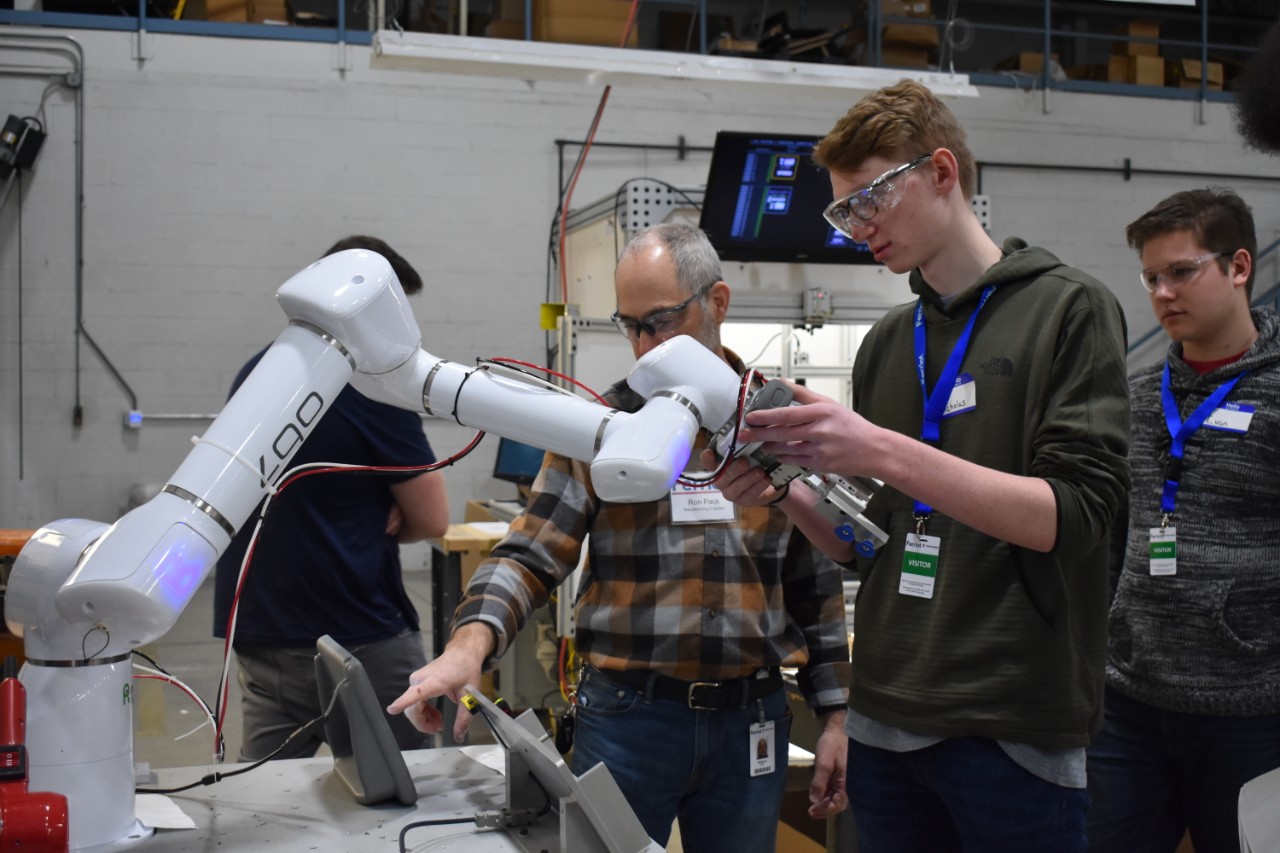

Ron Pack, Manufacturing Engineer, provides students with several new technology demonstrations, including collaborative robots (cobots) that assist with repetitive tasks and allow employess to do more complex work.

Students controlling the cobot using hand held touch screen. In this case, the cobots handle the repetitive task of moving the two parts to the ultrasonic welder (not visible in the photo). This permits employees to focus on tasks requiring more “brainpower.”

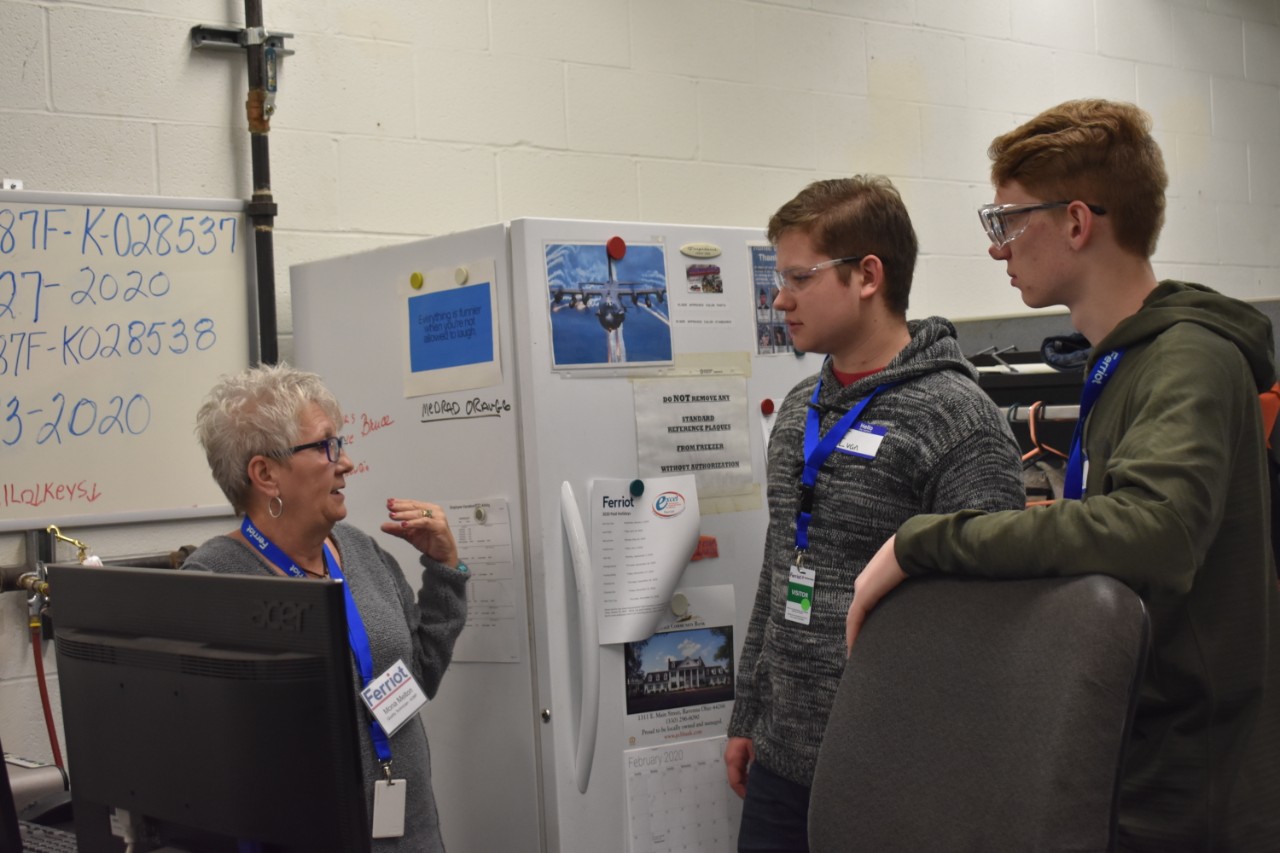

In the color lab at American Original Building products, Mona Melton, Quality Technician, takes the students on a tour of the quality inspection area. Special software is utilized to check color samples from production runs of injection molded shake siding for homes.

Mona discusses siding features and color inspection with the STEM school students.

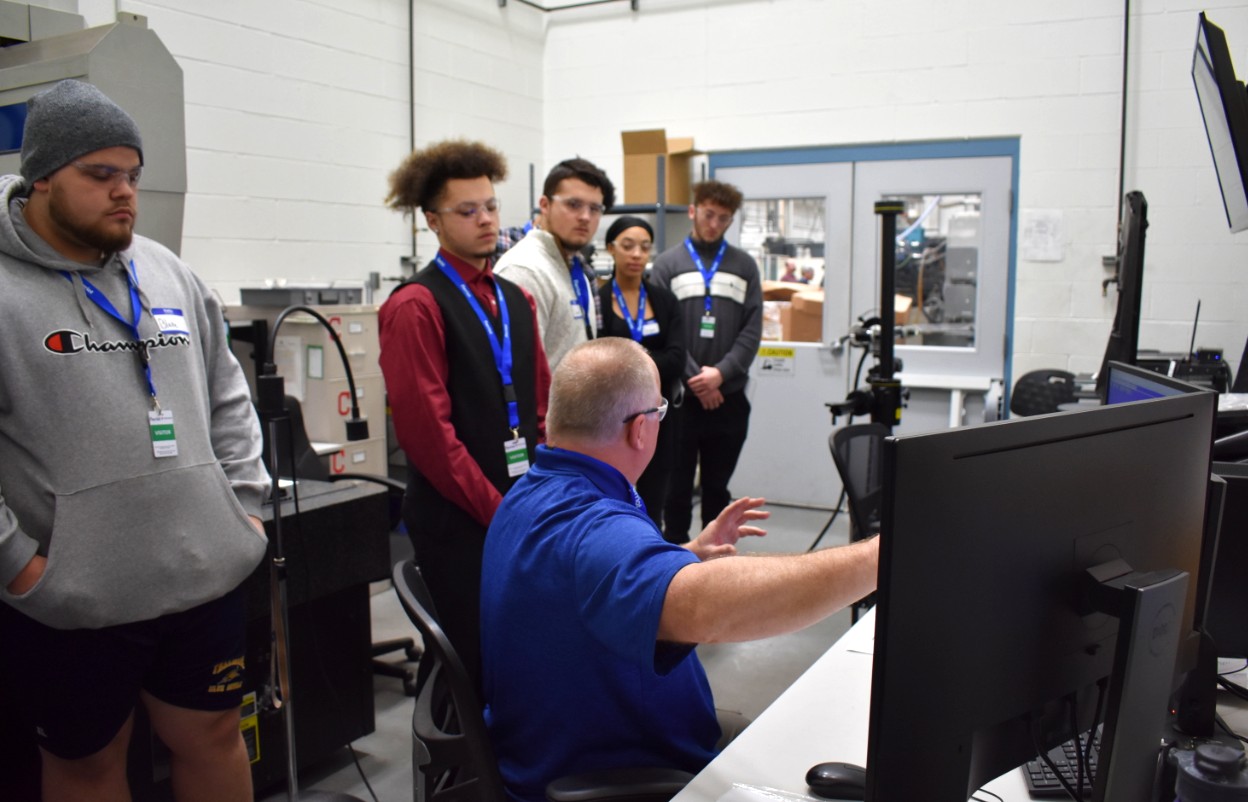

Numerous Engineering Services including Design for Manufacturing (DFM) and product design assistance are discussed. Here the student is looking at the 3D images of an injection molding tool design.

A STEM student studies a part with the advanced CAD software used by our Engineering team.

Marc Keeler, General Foreman, discusses several finishing operations in the paint finishing area.

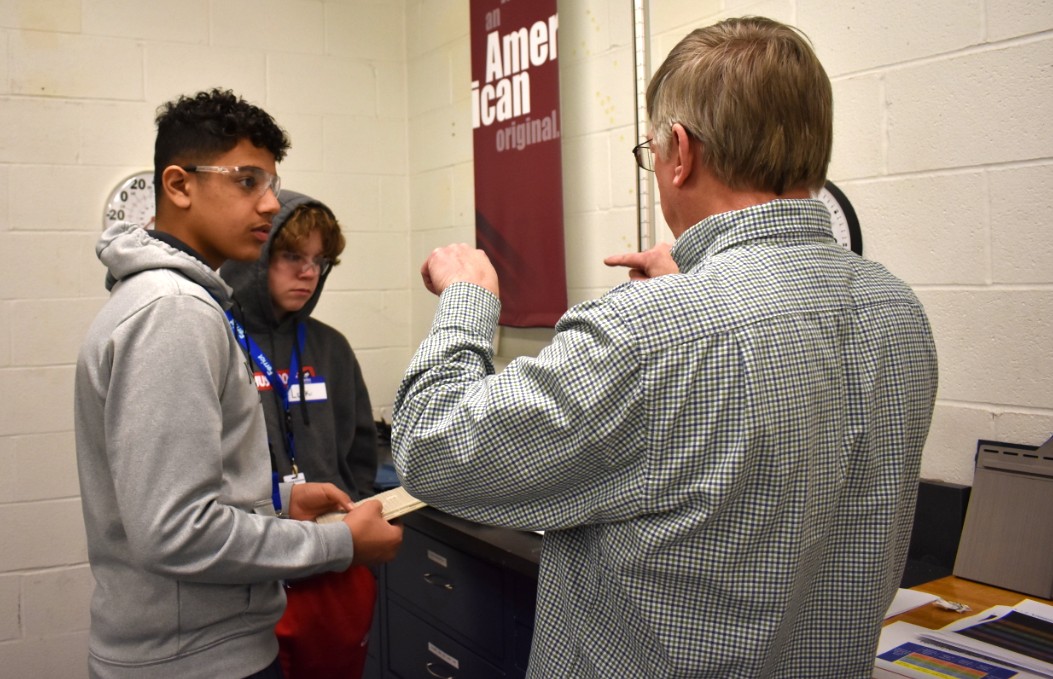

As part of a Total Quality Management (TQM) exercise, students work with Quality Supervisor, George Popov, measuring parts to determine if the parts are within specification tolerance.

Aaron Dadisman, Molding Manager, explained how the molding process works, beginning with the resin pellets, emphasizing how important resin selection can be to the final product.

Aaron Dadisman further explained the molding process at one of the larger presses.

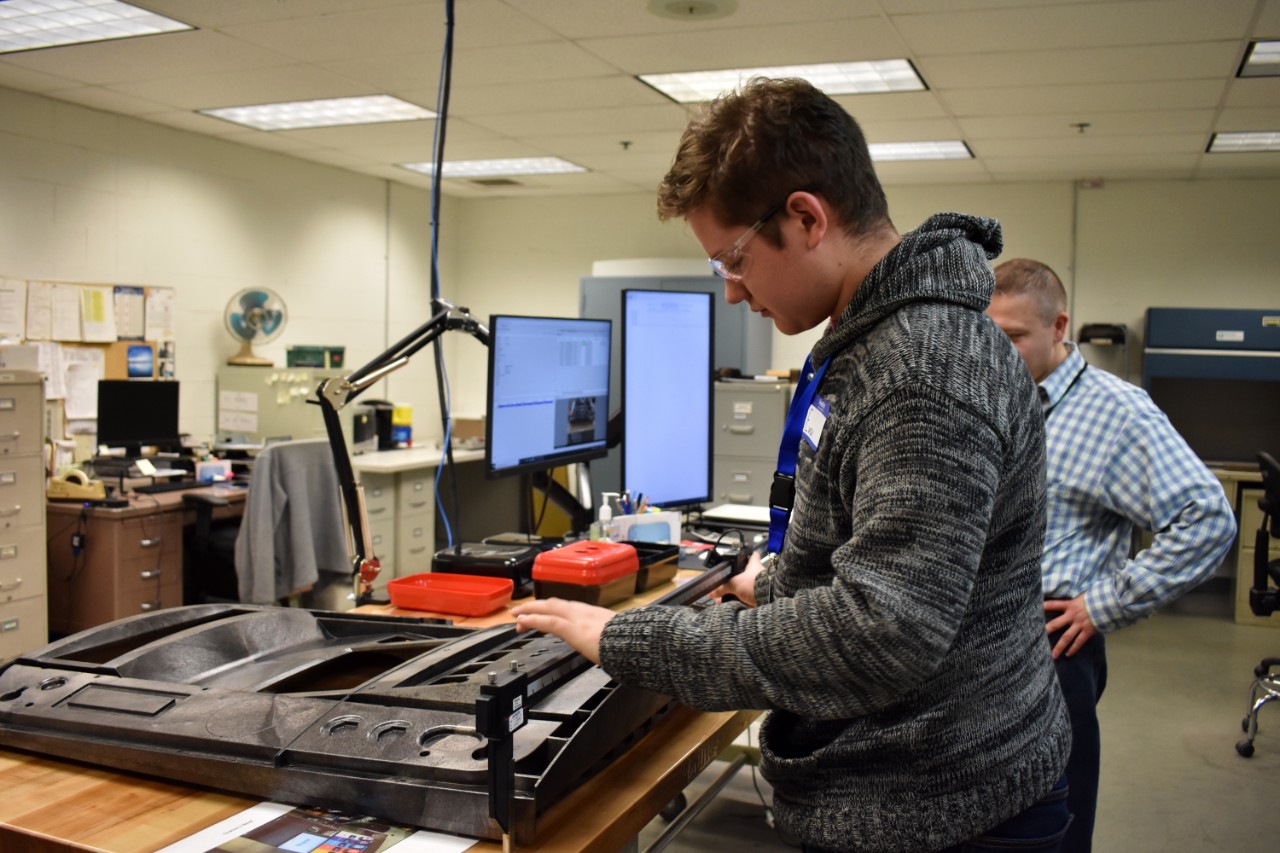

Walter Kravetz, Quality Technician, demonstrates the scanner technology used to ensure parts meet design specifications as parts of Total Quality Management (TQM).

Walter demonstrates how a CMM machine (coordinate measuring machine) measures the geometry of a part.

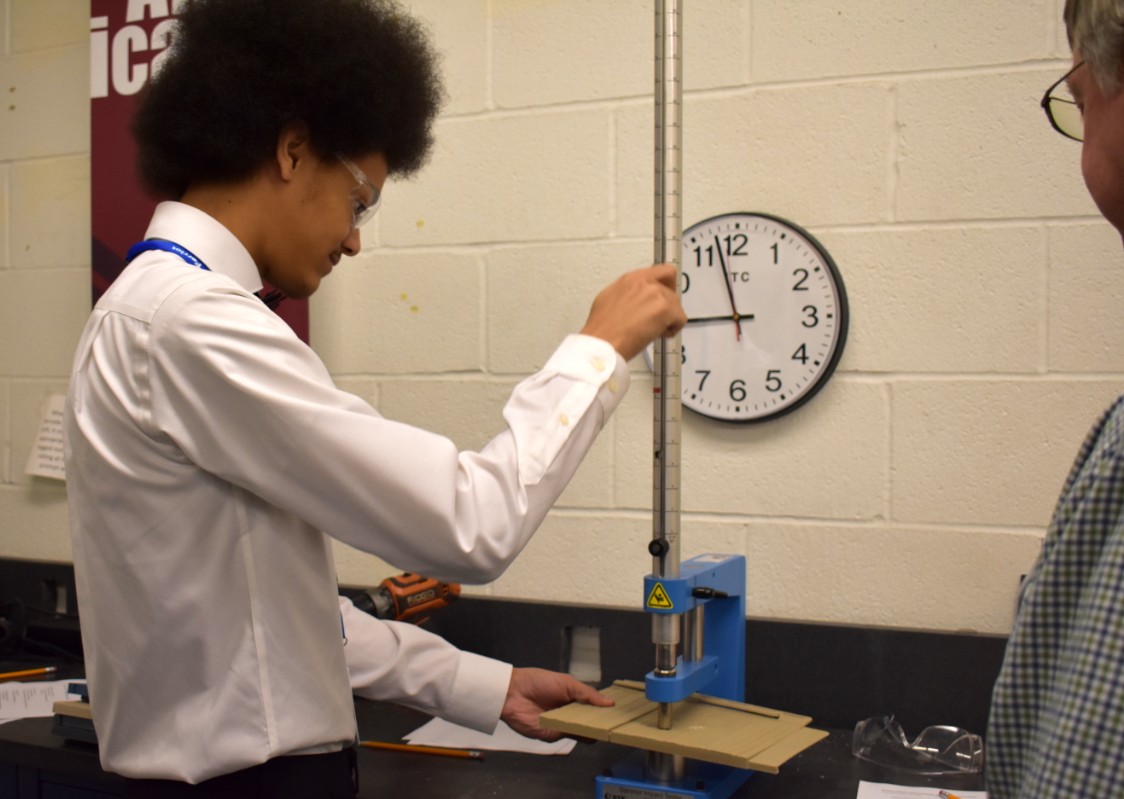

Dale Leopold, General Manager, spends time with students In the product testing area, where students are given the opportunity to give siding from American Original Building Products a rough time.

Student participates in an impact test to determine if siding strength meets specifications.

Training is an ongoing process for anyone choosing a career with Ferriot. Students were given an opportunity to ask the Ferriot experts questions about injection molding, engineering services, and other career paths.

Learn more: